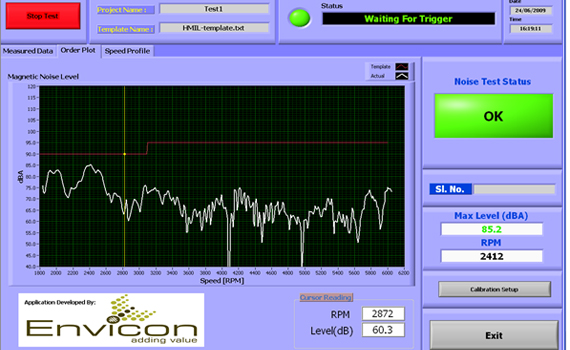

CUSTOMISED NOISE AND VIBRATION TESTING SYSTEM (End of The Line Testing For Automotive Alternatiors, Starter Motors, Washing Machine Motors)

Abnormal vibration and/or noise indicate the defect in the products. These defects could be due to design, manufacturing or assembly. Hence, noise and vibration signatures are used as an indicator of product quality. EVPL has provided many solutions for END OF THE LINE test system for qualification of the products using Noise and Vibration signatures. EVPL will undertake feasibility study to establish the possibility of using the Noise and vibration signature and identify the data processing methods which can be used to segregate the good and defective products. Based on the result of feasibility study, EVPL will design the test system, select the required sensors, data acquisition system and the application software. EVPL has successfully developed and supplied END OF THE LINE NOISE TEST SYSTEM for automotive alternators, starter motors, wiper motors, motor for washing machines etc.

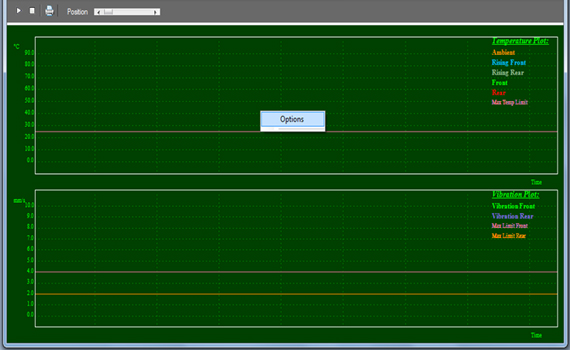

AUTOMATED SPINDLE TEST SYSTEM

EVPL also supplied automated spindle test system for testing high speed machine tool spindle by monitoring spindle vibration and temperature. The whole testing is fully automated as per the programmed schedule which runs without human intervention and generate detailed test report.

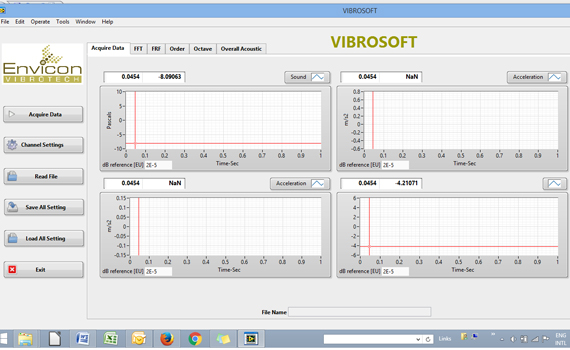

4 CHANNEL FFT ANALYSER FOR NOISE AND VIBRATION MEASUREMENT

EVPL has developed basic Noise and Vibration analyser Based on National Instrument Data Acquisition hardware. The analyser software is capable of measuring FFT, 1/N octave spectrum, order spectrum and overall noise level measurements. This will be a useful tool especially for beginners, Universities and industries.