VIBRATION DIAGNOSTICS AND TROUBLE SHOOTING

Many industrial equipment and machinery encounter higher noise/vibrations during installation/commissioning, operation and after refit. EVPL specializes in diagnosing and troubleshooting the noise and vibration problem and suggest suitable remedial measures. Various measurement and analysis techniques will be employed for trouble shooting. Typical machinery for which trouble shooting was carried out are Hydro Electric Generators, Gear box of steam turbine Generators, Gas Compressors, Fans and Blowers, DG sets etc.

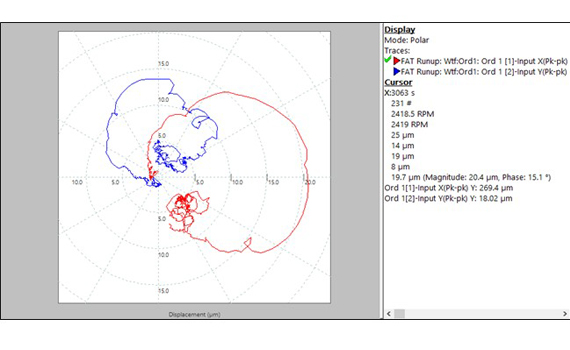

TURBO MACHINERY VIBRATION MEASUREMENT AND ANALYSIS

This involves measurement and analysis of shaft vibration of turbo machinery like Steam and gas turbines, compressors etc, Various measurements such as Bode Plots, Orbit plots, Shaft centerline plots, waterfall spectral plots are measured as part of vibration trouble shooting or to check conformance to standards(API,ISO etc) or Factory Acceptance Tests.

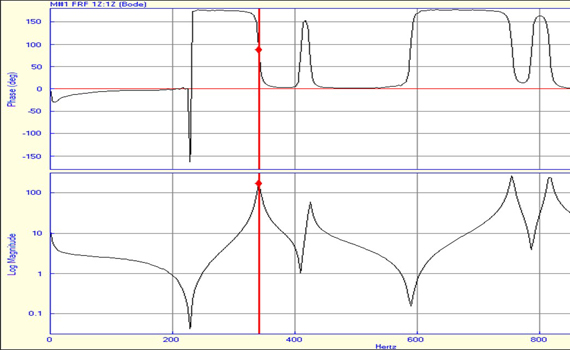

NATURAL FREQUENCY TESTING

Information about Natural frequency of machine components are vital for design validation. Natural frequency testing on components such as turbine blades, fan blades, automobile components such as break discs, break drum etc are measured by impact testing as part of design validation and noise and vibration trouble shooting.

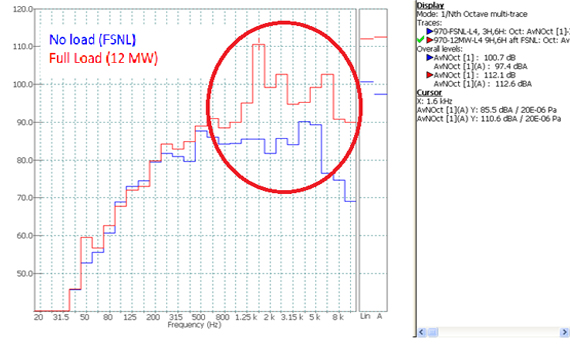

STRUCTURE BORNE AND AIRBORNE NOISE MEASUREMENT

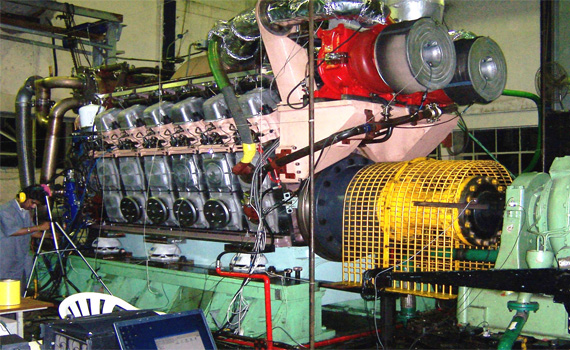

Noise and vibration radiation (also known as Structure Borne and Air Borne Noise) from naval ships and submarines is critical as these signals can be easily detected by sonars. Stringent limits for noise and vibrations are placed on equipment that goes on board Naval vessels. These equipment are tested for their conformance to various standards (MIL, ISO, NES etc.) at the factory inspection stage. EVPL has conducted Structure Borne and Air borne noise levels for many equipment which include DG sets, Turbines, Main Engines, STPs (Sewage Treatment Plants). RO plants, Pumps, Compressors, Hydraulic systems etc.

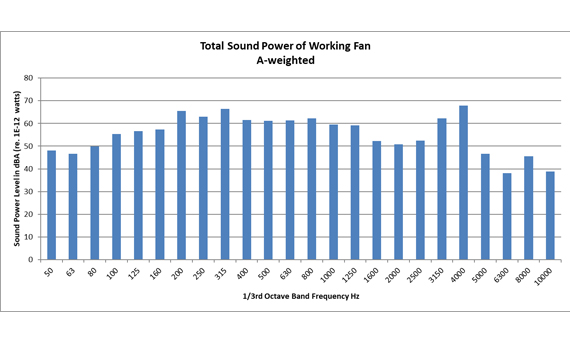

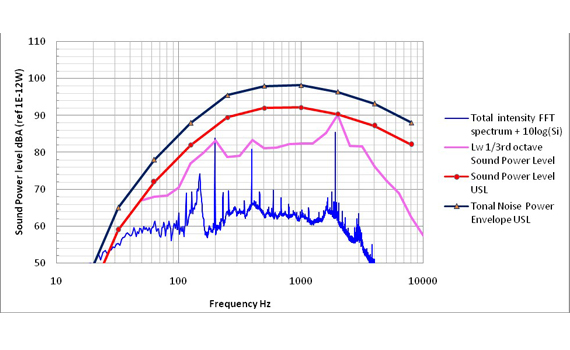

ACOUSTIC INTENSITY AND SOUND POWER

EVPL has the state of the art Acoustic Intensity Measuring System which can be used for Sound Intensity Measurement. Sound Intensity can be used for many purposes like Sound Power Determination, Noise Source Identification and Noise Source Ranking. Facilities at EVPL include GRAS sound Intensity Probe, Intensity and sound power measurement Software, Acoustic level and phase calibration system. EVPL has conducted many in-situ sound power measurements of various equipment which otherwise required Specialized test chambers such as Semi anechoic or reverberant chambers.

ONSITE BALANCING OF ROTORS

EVPL provide on-site balancing service to reduce unbalance induced vibrations in rotors. EVPL has carried out balancing of High Speed machine tool spindles to industrial fans and blowers to rotors of hydroelectric turbines etc.

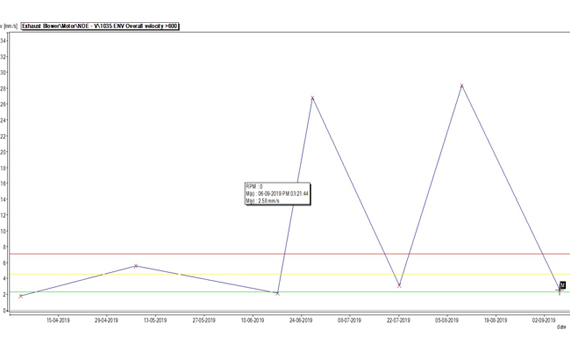

CONDITION MONITORING

EVPL has a dedicated team which provide predictive maintenance services through vibration monitoring. The tem is equipped with Vibxpert portable data collectors and OMNI TREND software, for vibration data collection, trending and analysis. Machinery problems such as unbalance, misalignment, bearing defects are identified well in advance and required corrective actions are taken before the machine condition reaches alarm levels. EVPL has special expertise in vibration monitoring of machine tools and manufacturing equipment where not only the machine health but quality of the manufactured product is also affected by higher vibrations.

ENVIRONMENTAL NOISE MEASUREMENT

Noise Assessment is the first step in any noise control measure. Continuous Exposure to higher noise levels are detrimental to the human beings working in noisy environment. EVPL carryout Environmental noise measurements and has facilities to measure various parameters Such LpA, LeqA, Lmax, Lmin, 1/1 and 1/3 octave band noise spectra.

NOISE AND VIBRATION MEASUREMENTS AS PER STANDARDS MIL, ISO, IEC, API, NES, IS etc

NOISE and vibration measurements has become an essential part of product testing and acceptance criteria. Most often, products need to conform to various standards before acceptance by the end customer. EVPL possess the required expertise and resources for measurement of Noise and Vibrations according to various standards such as IS, ISO, IEC, MIL, API etc., Some of the products tested for noise and vibrations are Shipboard equipment (MIL and ISO), steam turbines, Electrical generators, Wind generators, Gear Box of turbines, Wind Turbine etc (IEC, IS, ISO, API)